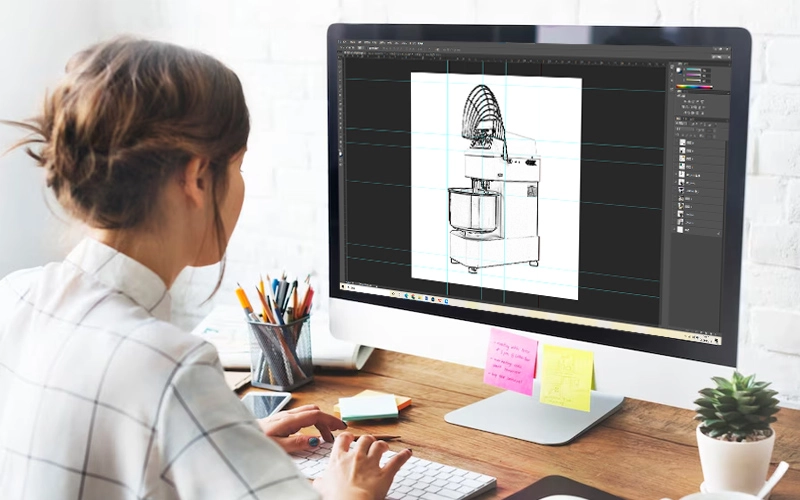

OEM Solutions for Spiral Dough Mixers

We specialize in providing customized Original Equipment Manufacturer (OEM) solutions for spiral dough mixers to meet the specific needs of our partners.

Our commitment to quality, innovation, and customization enables us to support your brand growth while providing high-performance equipment.

Why Choose Our Dough Mixers OEM Solutions

Customization options for Spiral Dough Mixers

We understand that every brand has unique needs.

Our customization options are designed to help you create the perfect spiral mixer to meet your specific needs and enhance your brand image.

01. Design & Aesthetics

● Color Options: Choose from a variety of colors to match your brand's identity. We can customize exterior paint and finishes to ensure your mixer stands out in any kitchen environment.

● Logo Placement: Add your company logo to the mixer to enhance brand recognition. Options include placement on the mixer body, control panel, or other prominent locations.

● Custom Design Elements: Work with our design team to incorporate unique design elements that reflect your brand's style, including decals, patterns, and special shapes.

02. Technical Specifications

● Motor Power: Choose the motor power that suits your production needs. We offer a variety of options, from standard motors to high-performance motors to accommodate different types of dough and mixing speeds.

● Bowl Capacity: Choose from a variety of bowl sizes to meet your production volume needs. Whether you need a small capacity for manual batches or a large bowl for large-scale production, we have you covered.

● Mixing Speed: Customize mixing speed settings to optimize performance for different types of dough. Our mixers can be adjusted for high-speed mixing or more gentle kneading as needed.

03. Control System

● User Interface Customization: Customize the control panel to your specific needs. Options include a touchscreen interface, programmable settings, and manual controls for ease of use and versatility.

● Automation: integrate automation options such as timers, batch settings, and auto-off features to increase operational efficiency and consistency.

04. Material Options

● Bowl Material: Choose from a variety of bowl materials, including stainless steel, aluminum, and other food-safe options to ensure durability and meet food safety standards.

● Housing Material: Choose the material of the mixer housing to provide additional insulation or enhance durability.

05. Performance Enhancements

● Temperature Control System: Customize the mixer to have temperature control for specific types of dough, ensuring that the optimal temperature is maintained during mixing to ensure the best dough quality.

● Noise Reduction Technology: Choose sound insulation enhancements to minimize operating noise, making the mixer suitable for a variety of kitchen environments.

06. Extra Features

● Safety Features: Integrated safety guards, emergency stop buttons and other safety enhancements to ensure a safe operating environment.

● Accessories and attachments: Choose from a range of optional accessories such as dough scrapers, stirrers and mixing bowls to enhance functionality and versatility.

OEM through our products

Spiral Dough Mixer customization partnership process

We pride ourselves on providing a seamless partnership experience.

Our structured process ensures we fully understand your needs and deliver a high-quality spiral mixer to meet your requirements.

01. Initial Consultation

● Understanding Your Needs: We begin with an in-depth discussion to understand your business goals, production needs and specific requirements for a spiral mixer.

● Information Gathering: During this stage, we gather information about your brand, target market and any specific features you would like to incorporate.

02. Proposal Development

● Customized Solutions: Based on the initial consultation, our team develops a tailored proposal including design concepts, technical specifications and pricing.

● Review & Feedback: We present the proposal to you for review. Your feedback is essential to refine the design and ensure it meets expectations.

03. Design Approval

● Finalize the design: Once we receive your approval of the proposal, our design team will create detailed drawings and 3D models of the spiral dough mixer.

● Prototype development (if necessary): In some cases, we may develop a prototype to demonstrate the design and functionality. This allows us to make any adjustments before full production.

04. Production Planning

● Scheduling: We create a production schedule that outlines the timeline for manufacturing, quality control, and delivery.

● Material Selection: Confirm the materials and components used in the manufacturing process to ensure they meet your quality standards.

05. Manufacturing

● Quality Assurance: Throughout the production process, we follow strict quality control measures to ensure that the final product meets all specifications.

● Regular Updates: We inform you of the progress of production through regular updates to allow for any adjustments if necessary.

06. Final Inspection

● Quality Inspection: Before shipping, each spiral dough mixer is rigorously tested and inspected to ensure it meets our quality standards and your specifications.

● Documentation Provision: We provide all necessary documentation, including certificates of compliance and user manuals.

07. Shipping & Delivery

● Logistics Coordination: We coordinate shipping logistics to ensure timely delivery to your designated location.

● Tracking Information: You will receive tracking information to monitor the shipping status of your shipment.

08. After-Sales Support

● Installation & Training: Our team can assist with the installation of your new spiral mixer and provide operational training to your staff.

● Ongoing Support: We provide ongoing technical support and maintenance services to ensure the longevity and optimal performance of your mixer.

09. Feedback & Continuous Improvement

● Collecting Feedback: After installation, we solicit your feedback to understand your experience and possible areas of improvement.

● Iterative Process: Your feedback helps us refine our processes and products to ensure we continually meet and exceed your expectations.

Frequently asked questions

Here you will find detailed information about our company, products, and our OEM/ODM capabilities.

For OEM

What quality control measures are in place during production?

We follow a strict quality control protocol during production, including regular inspection and testing of materials and components. Each mixer undergoes a final inspection before shipment to ensure it meets our high standards and your specifications.

Can I request a prototype before full production?

Yes, we can develop a prototype based on your approved design. This allows you to evaluate functionality and make necessary adjustments before we go into full production.

What customization options are available?

We offer a wide range of customization options, including:

● Design and aesthetics (color, logo placement)

● Technical specifications (motor power, bowl capacity)

● Control system (user interface, automation features)

● Material options (bowl and housing materials)

● Performance enhancements (temperature control, noise reduction)

What kind of after-sales support do you provide?

We provide ongoing technical support, maintenance services, and assistance with any issues that may arise after purchase. Our team is always available to help you ensure your mixer runs smoothly.

How long does the customization process typically take?

The customization process typically takes 2 to 4 weeks, depending on the complexity of the design and specifications. This time frame includes initial consultation, design approval, production, and quality inspection.

How to Choose the Right Dough Mixer Manufacturer

How to Choose the Right Dough Mixer Manufacturer

Choosing the right spiral mixer manufacturer is essential to ensure quality, performance, and a successful partnership. The following key factors need to be considered:

Experience and Expertise

01

Look for a manufacturer with a proven track record in the food machinery industry, especially in producing spiral mixers. An experienced manufacturer will understand the unique challenges and needs of your business.

Quality Standards

02

Make sure the manufacturer follows strict quality control measures and industry standards. Certifications such as ISO and CE can demonstrate its commitment to quality and safety.

Customization Capabilities

03

Choose a manufacturer that offers a wide range of customization options. This includes not only design and branding, but also technical specifications for your specific needs.

Production Capabilities

04

Evaluate the manufacturer's production capabilities to ensure they can meet your needs. This includes their ability to effectively handle both small and large orders.

Technical Support and Service

05

A reliable manufacturer should provide comprehensive support, including installation, training, and after-sales service. Good communication and responsiveness are essential for a successful partnership.

Innovation and Technology

06

Look for manufacturers that invest in the latest technology and innovation in food machinery. This can improve performance, energy efficiency, and product life.

Testimonials and Case Studies

07

Research the manufacturer's reputation by looking at customer reviews and case studies. This will provide you with insights into its reliability, quality, and service.

Price and Value

08

While cost is an important factor, it should not be the only consideration. Evaluate the value you get for the price you pay, including quality, support, and customization options.

Location & Logistics

09

Consider the manufacturer’s location and logistics capabilities. A manufacturer close to your operations may reduce shipping time and costs.

Sustainable Practices

10

If sustainability is important to your brand, check that the manufacturer uses environmentally friendly manufacturing processes and materials.

Send My OEM Customization Request

If you are looking for a reliable partner to meet your OEM needs for spiral dough mixers, we are here to serve you.

Contact us today to discuss your project needs and learn how we can support your brand’s success.

Contact us for a tailor-made dough mixer solution

If you are looking for a reliable, high-performance dough mixer to enhance your baking or food processing operation, we are here to provide you with the perfect solution.